Introduction

Precision and efficiency are essential for success in the quick-paced pharmaceutical industry. Companies are constantly seeking for ways to optimise profitability and streamline processes in order to accomplish these goals. Batch costing is a useful technique that can aid in achieving these goals. Pharmaceutical producers can better understand their production costs, enhance decision-making, and promote sustainable growth by implementing batch costing approaches. In this piece, we look at the subject of batch costing in the pharmaceutical sector, highlighting its benefits and showing how it may completely transform the way pharmaceutical manufacturers conduct business.

The Role of Batch Costing in Pharmaceutical Cost Analysis

Batch costing is a cost analysis technique used to determine the cost per unit of a batch or lot of products. In the pharmaceutical industry, it allows manufacturers to calculate the cost associated with each batch of drugs produced, considering all the expenses incurred during the production cycle. By analyzing costs at the batch level, pharmaceutical companies can gain valuable insights into their cost structures, identify inefficiencies, and make informed strategic decisions.

According to industry experts, batch costing provides a granular view of production costs, enabling companies to identify areas of improvement. Dr. Emily Johnson, a pharmaceutical cost analyst, states, "Batch costing allows us to break down the production costs at a granular level, providing valuable insights into resource utilization and cost drivers. This information empowers decision-makers to optimize processes and enhance profitability."

Batch costing allows us to break down the production costs at a granular level, providing valuable insights into resource utilization and cost drivers. This information empowers decision-makers to optimize processes and enhance profitability.

Dr. Emily Johnson, a pharmaceutical cost analyst

Batch Costing Computation

The production process typically involves several stages, including raw material procurement, formulation, compression, coating, and packaging.

Batch: In this example, a batch refers to a specific quantity of a Product produced in a single production run. For instance, a batch may include a product output of 10,000 units of a Product.

Stages: Each stage in the production process represents a distinct phase where a certain intermediate or final product is produced. A finished product may have multiple intermediate stages before the final product is produced. Every stage produces certain primary products and by-products of a specific batch identified by a batch number. Each stage requires different resources and incurs costs.

Resources Consumed: At each stage, various resources are consumed, including raw materials, labor, equipment, utilities, and quality control. Raw materials such as active pharmaceutical ingredients (APIs), excipients, and packaging materials are required. Labor costs encompass the wages of production workers, technicians, and quality control personnel. Equipment costs include maintenance, depreciation, and energy consumption. Utilities involve electricity, water, and other utilities required for production.

By-Products: During the production process, some stages may generate by-products. For example, in tablet production, the compression stage may produce scrap tablets or excess coating material. These by-products are not the primary intended product and have a potential value.

Treatment of By-Products: In batch costing, the cost of by-products is typically deducted from the overall resource cost to determine the batch cost. The value of the by-products can be assessed separately and used to offset the total cost. This approach ensures that the batch cost reflects the expenses associated with the primary product only, providing a more accurate understanding of its production cost. By incorporating batch costing, the pharmaceutical company can accurately determine the cost per unit of the tablet batch. This allows them to analyze the cost breakdown, identify inefficiencies in each stage, and make informed decisions regarding resource allocation, process optimization, and pricing strategies. Additionally, the cost reduction attributed to the by-products helps minimize the overall expenses and improve profitability.

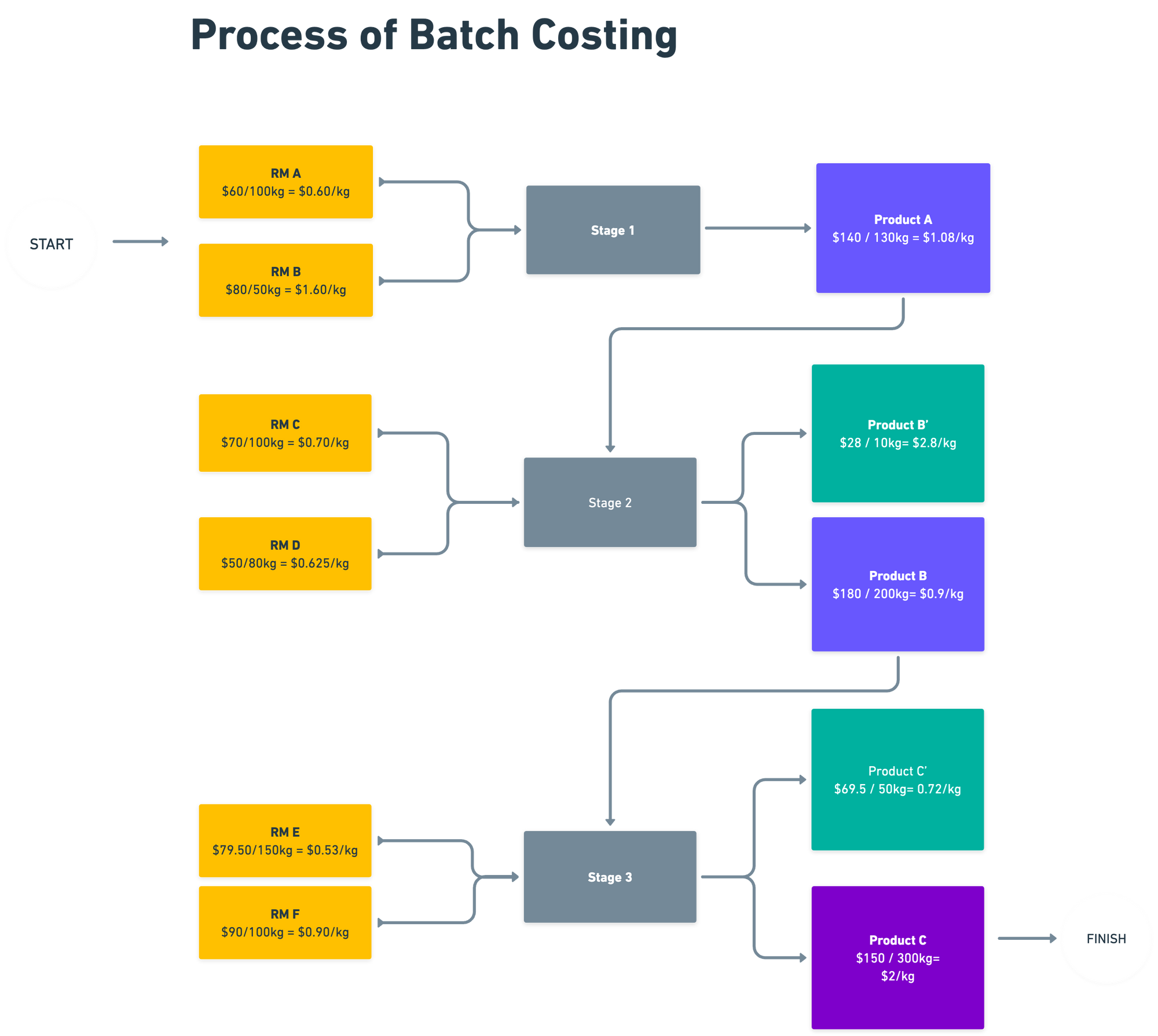

Let's work through an example of batch costing using hypothetical information. We'll use the stages and raw materials provided and calculate the costs at each stage for the final product, Product C.

Stage 1: In Stage 1, we produce Product A from raw materials RM A and RM B.

Input Resources:

Input Resource Quantity Total Cost Cost per Unit RM A 100kg $60 $0.60/kg RM B 50kg $80 $1.60/kg

Output Resources:

Output Resource Quantity Total Cost Cost per Unit Product A 130kg $140 $1.08/kg

No by-products are generated in Stage 1.

Stage 2: In Stage 2, we produce Product B from raw materials RM C, RM D, and the output Product A from Stage 1.

Input Resources:

Input Resource Quantity Total Cost Cost per Unit RM C 100kg $70 $0.70/kg RM D 80kg $50 $0.625/kg Product A 100kg $108 $1.08/kg

Output Resources:

Output Resource Quantity Total Cost Cost per Unit Product B 200kg $180 $0.9/kg By-product A' 10kg $28 $2.8/kg

Stage 3: In Stage 3, we produce Product C from raw materials RM E, RM F, and the output Product B from Stage 2.

Input Resources:

Input Resource Quantity Total Cost Cost per Unit RM E 150kg $79.50 $0.53/kg RM F 100kg $90 $0.90/kg Product B 100kg $90 $0.9/kg

Output Resources:

Output Resource Quantity Total Cost Cost per Unit Product C 300kg $150 $2/kg By-product B' 50kg $69.5 $0.72/kg

By following this 3-stage batch manufacturing process and considering the costs at each stage, by-product generation, and the raw materials used, the final cost per unit of Product C is $2 per kilogram.

Improved Transparency and Precision in Costing

Pharmaceutical manufacturers can benefit from batch costing as it enables them to gain a holistic understanding of their cost structure, leading to more accurate financial reporting. This approach involves assigning costs to individual batches, allowing companies to accurately allocate expenses related to raw materials, labor, equipment, utilities, packaging, quality control, and other production-related factors. Such detailed cost analysis empowers decision-makers to identify areas of cost overruns, optimize resource allocation, and implement cost-saving measures where necessary.

Studies have shown that implementing batch costing methodologies can significantly enhance cost transparency and precision. Research shows that CM processes in the USA result in higher NPVs than batch manufacturing processes., leading to enhanced financial management and improved profitability.

Effective Pricing and Profitability Management

To achieve effective pricing and profitability management, pharmaceutical companies must have accurate batch costing. This is crucial in developing competitive and profitable pricing strategies. By analyzing the cost breakdown for each batch, companies can determine appropriate profit margins while considering factors such as research and development costs, regulatory compliance expenses, and market demand. This valuable information enables businesses to establish optimal pricing structures that take into account both the cost of production and market dynamics, leading to increased profitability while remaining competitive in a highly regulated industry.

Improved Decision-Making and Resource Allocation

The use of batch costing in pharmaceutical manufacturing facilitates informed decision-making and efficient allocation of resources. By examining the costs associated with each batch, manufacturers can identify profitable products, streamline production processes, and optimize resource allocation. This approach minimizes waste, reduces inventory holding costs, and enhances overall operational efficiency. Additionally, precise cost data is instrumental in evaluating the financial feasibility of new product launches and assessing the profitability of the existing drug portfolio.

Compliance and Audit Preparedness

Adherence to regulatory requirements is of utmost importance in the pharmaceutical industry. Batch costing helps in achieving compliance and audit preparedness by keeping a record of all the costs associated with each batch. This detailed documentation ensures transparency and traceability, which helps companies meet regulatory standards and demonstrate compliance during audits. Pharmaceutical manufacturers can reduce the risk of non-compliance and avoid potential financial penalties or damage to their reputation by incorporating batch costing into their financial management systems.

A regulatory compliance expert emphasizes the importance of batch costing in the pharmaceutical industry, stating, "Accurate cost allocation through batch costing is crucial for regulatory compliance. It allows companies to demonstrate transparency, traceability, and adherence to financial regulations, ensuring a strong compliance posture during audits."

John Anderson, a regulatory compliance expert